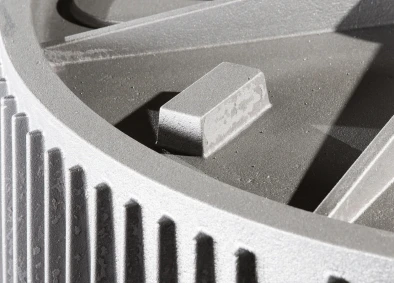

Soucy Belgen Drummondville uses 25% more recycled material!

The unit is reducing its use of virgin material in favor of recycled material, while maintaining the quality of its cast parts!

The unit is reducing its use of virgin material in favor of recycled material, while maintaining the quality of its cast parts!

The unit is reducing its cardboard box consumption by reorganizing its warehouse logistics!

François Beaudet, Process, Quality and Development Director at our Soucy Belgen Sainte-Claire foundry, shares his unconventional career path and his highly stimulating role!

A Quebecer who moved to Brazil for work shares the challenges he faced, what he learned, and tips for others who are thinking of moving to another country.

From processing to molding, several subsidiaries are involved in the rubber manufacturing process for our track systems.

Let us design your accessories. Our one-of-a-kind, custom plows for off-road vehicles are a sure-fire way to enhance your brand image.

Several factors impact their performance, durability and ability to function effectively in challenging environments.

Engineered and developed entirely in-house, this robotized bonding system achieves high precision applying adhesive to reinforcement inserts prior to rubber molding.

Discover how combined rubber enhances motorized equipment performance. Analysis of benefits, applications and innovations for the powersport sector.