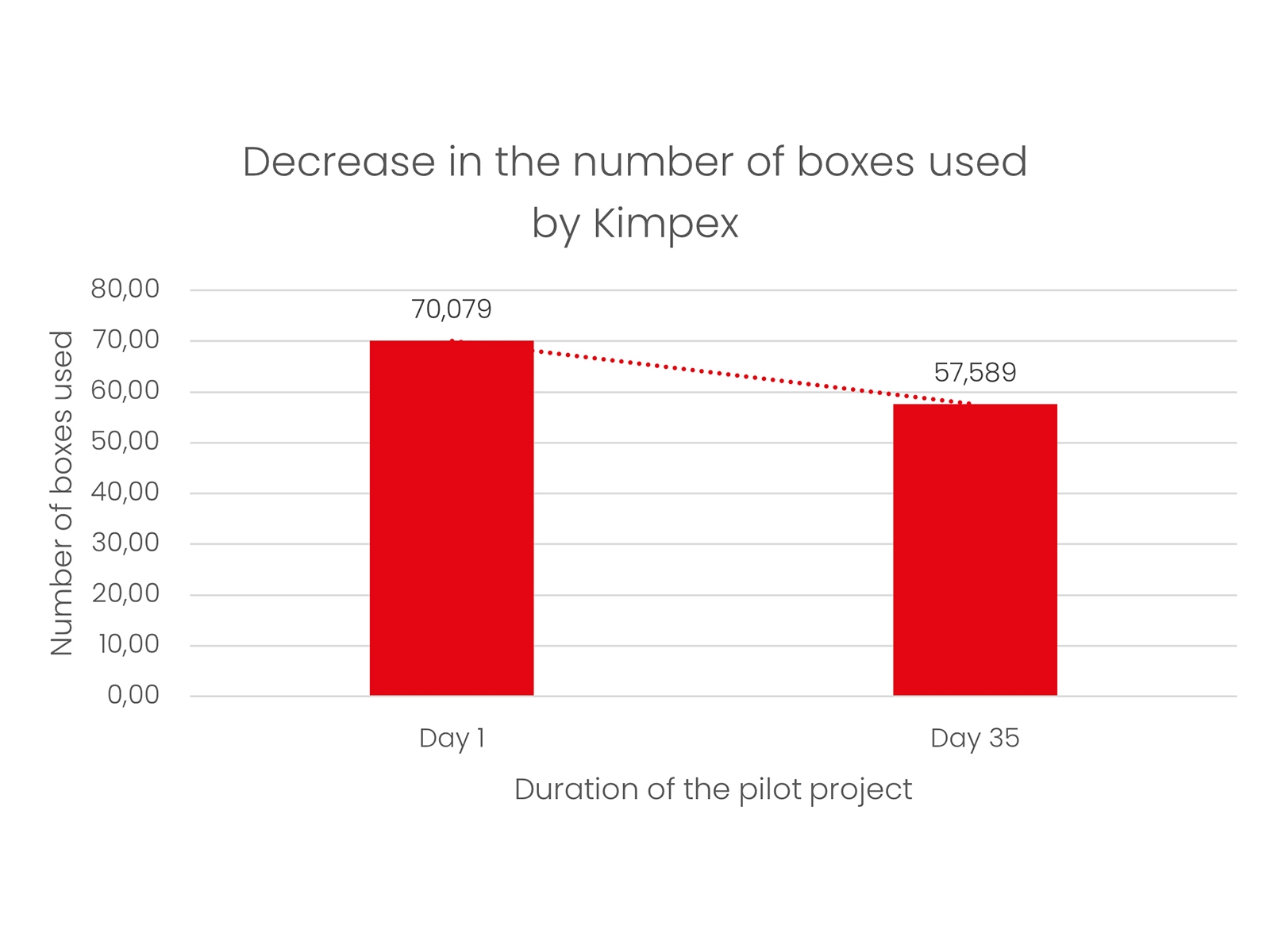

Last year, Kimpex received many comments from clients and staff about the number of boxes the company uses for its orders. And the company took action!

We are a distributor of high-quality powersports products, shipping a wide range of products to over 3,500 retailers across Canada, the United States, and Europe.