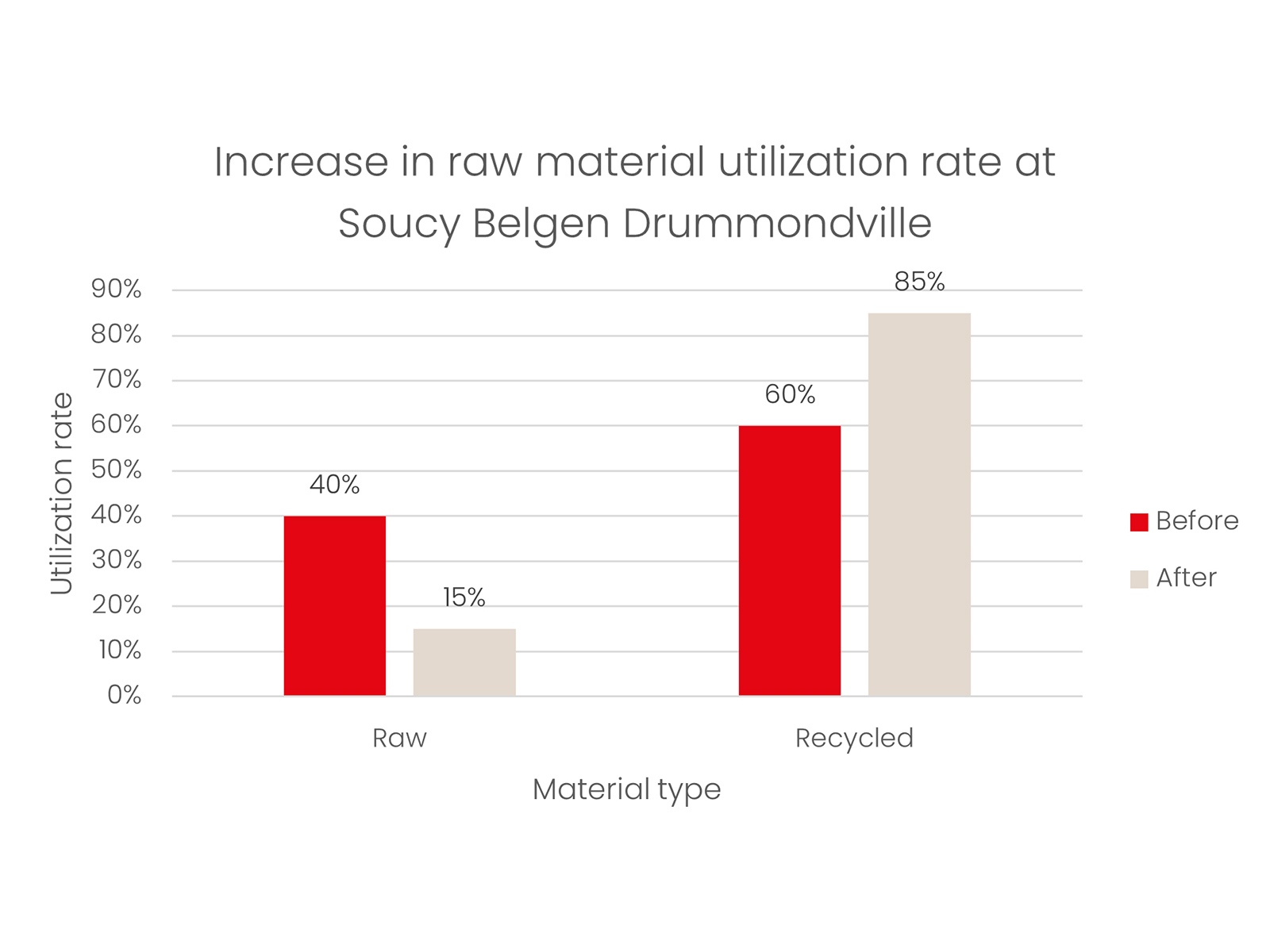

Over the past year, Soucy Belgen Drummondville has sought to reduce its procurement costs by at least 10%. We can proudly say mission accomplished!

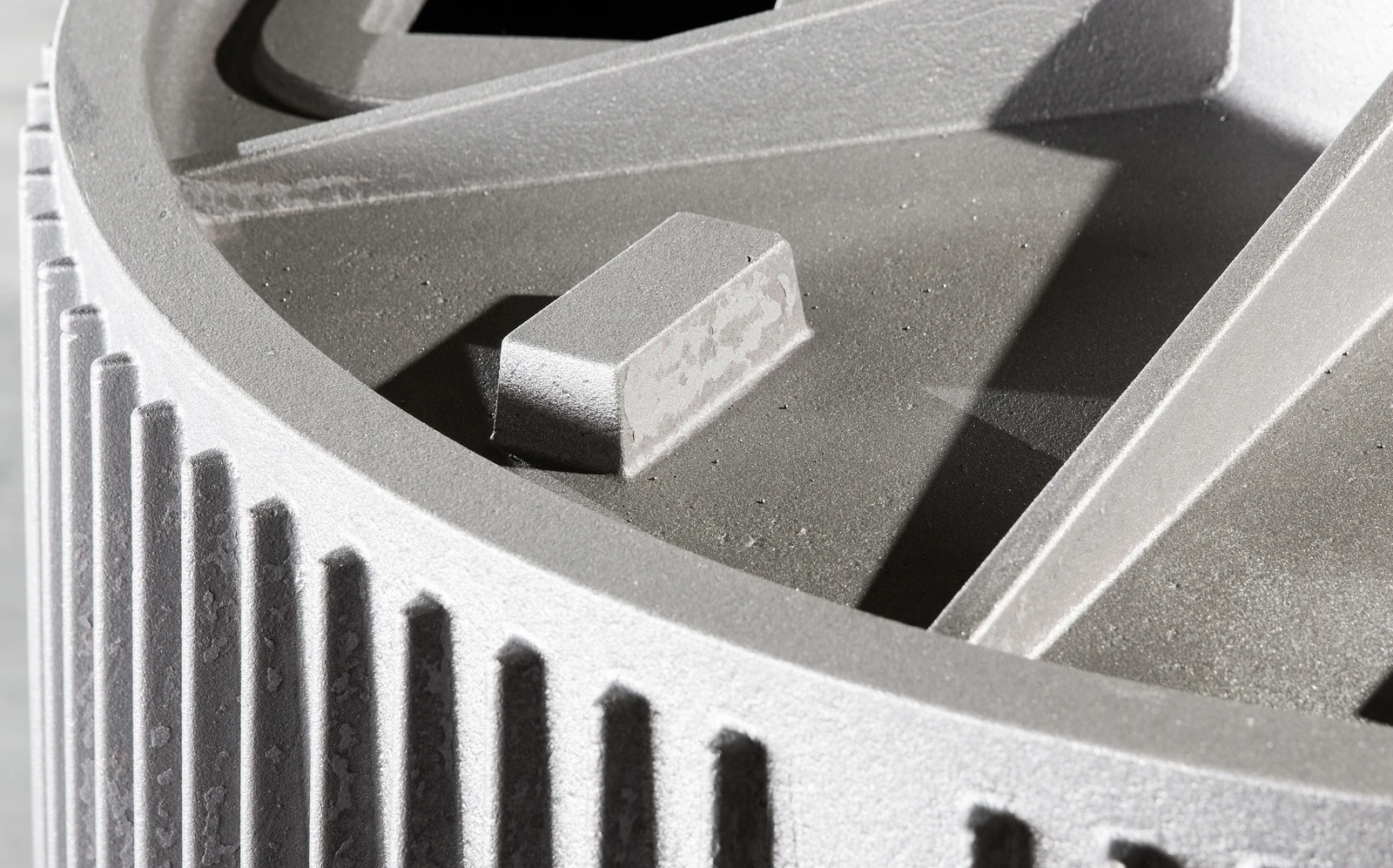

Our unique processes are designed for the production of large gray iron, ductile iron, ADI, and steel parts.