Our manufacturing processes

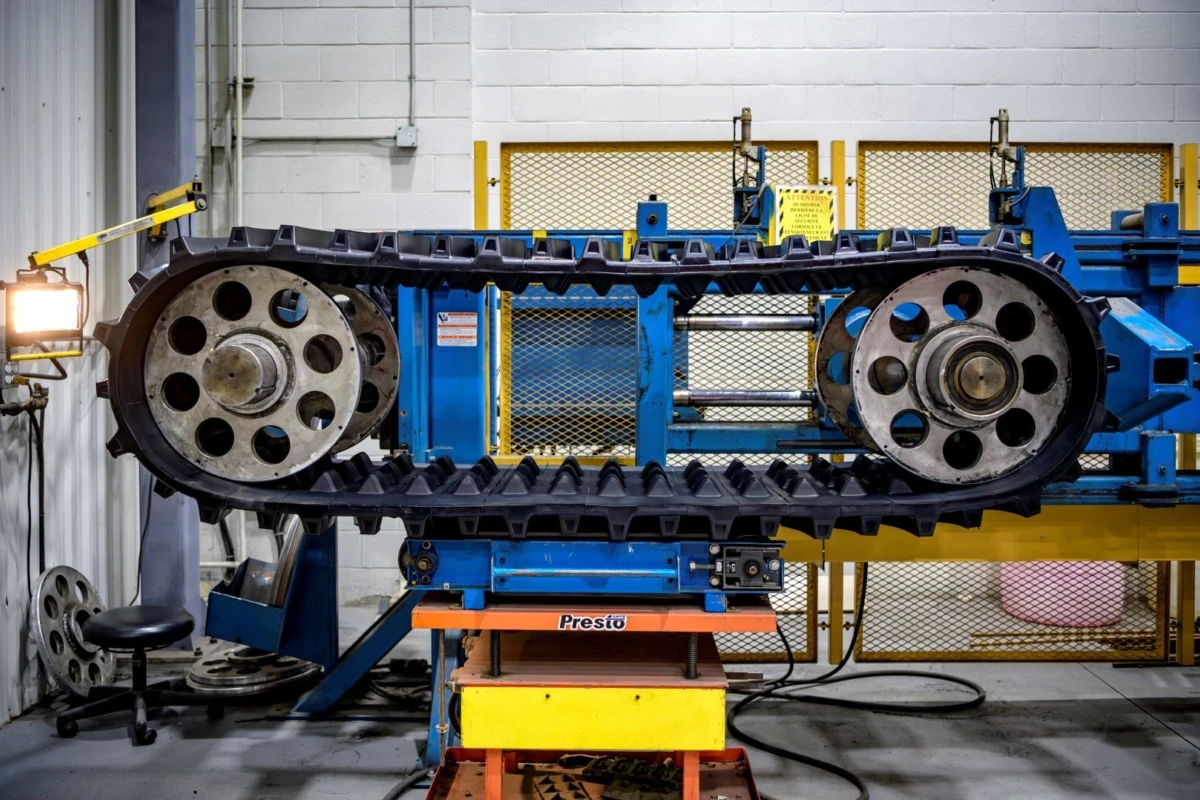

Our specific moulding process optimizes track manufacturing by allowing the integration of internal alloy with rubber, offering the flexibility to adapt to your specific needs.

Additionally, the construction of the tracks incorporates steel cables which are strategically placed to optimize the track and ensure its durability.

Compression moulding neutralizes the adverse effects of the steel cables on the performance of the rubber tracks.

This approach enables us to offer dedicated solutions by tailoring the manufacturing of tracks to your specific requirements.