Compression moulding

The hot direct compression technique for UHMW-PE enables us to integrate additional materials like steel (e.g., steel flanges) or rubber (via overmoulding), broadening the range of possibilities.

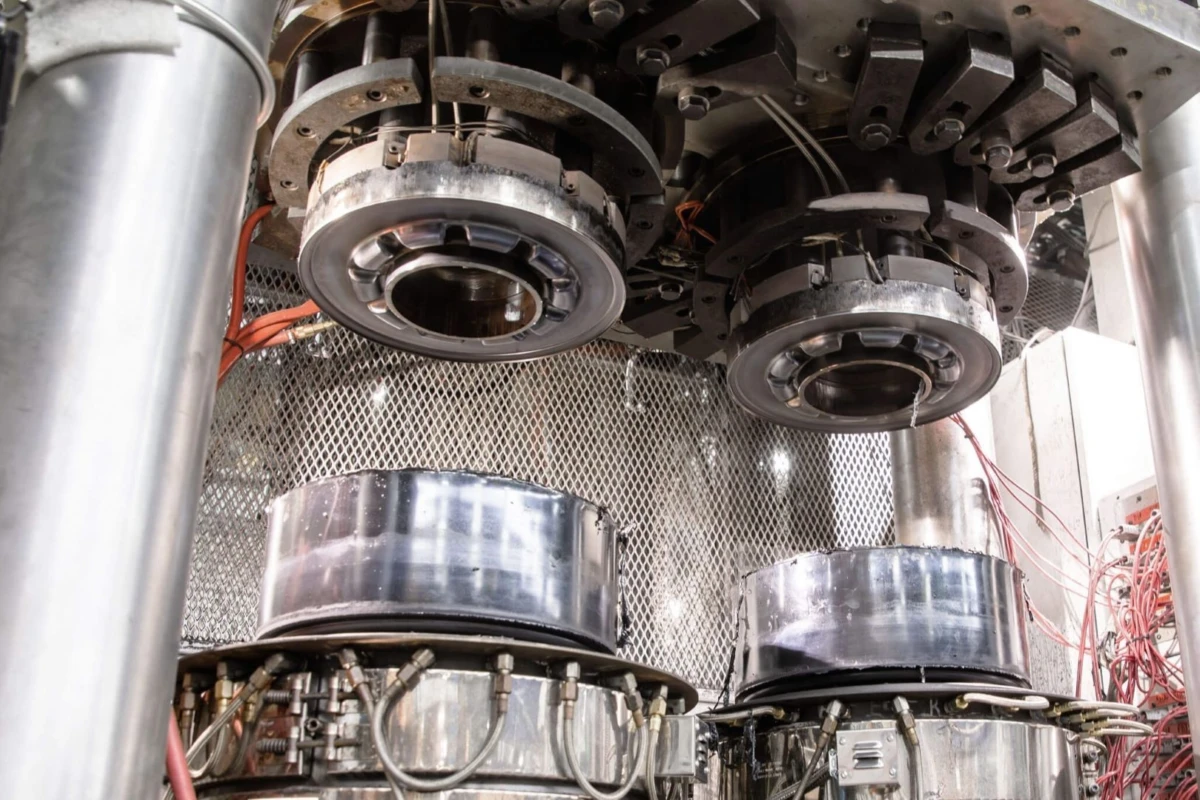

With over 150 presses ranging from 100 to 1000 tons at our disposal, we're equipped for various complex assemblies.