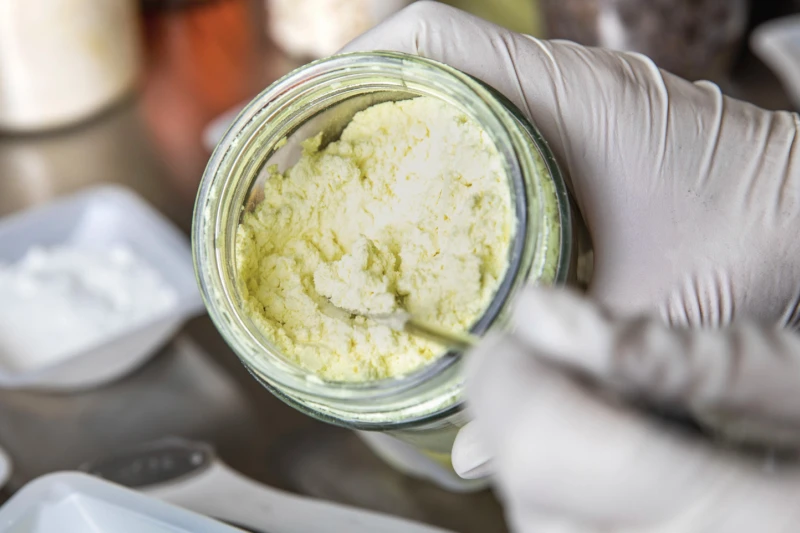

Low-VOC adhesives

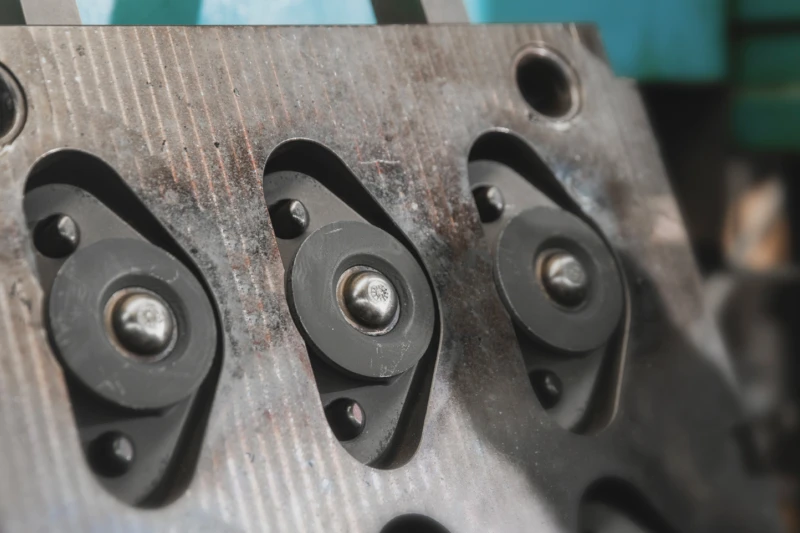

Depend on our mastery of different adhesion techniques and our extensive knowledge of adhesive types to respond to your adhesion challenges. Steel, aluminum and certain plastics can all be bonded to rubber. Our experts use adhesives that provide additional protection against corrosion, without adding a step in the treatment of the part.