Rubber is a fascinating material used in many industrial sectors. You can find it almost anywhere, but do you really know what rubber is and how it’s made? In this article, we’ll introduce you to the world of rubber and explore its properties, manufacturing processes and applications.

What is an elastomer?

To explain rubber, we’ll start with the basics.

An elastomer is a polymer that has elastic properties. That means it can deform under stress but returns to its original shape when stress is removed. Elastomers are therefore materials that are stretchable, compressible and reversible.

OK... but what’s a polymer?

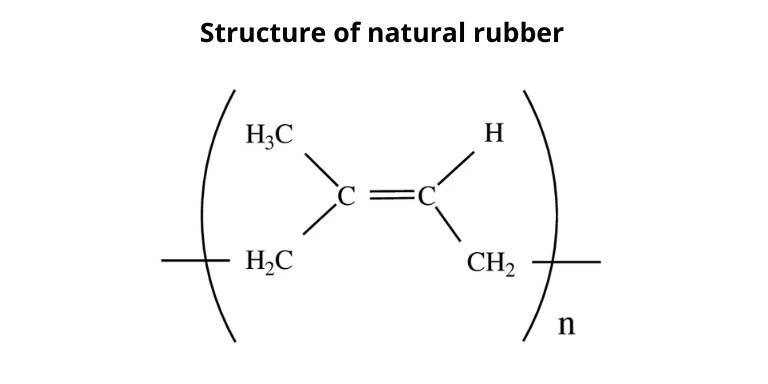

The term “polymer” hails from the Greek words polus, meaning “many”, and meros, meaning “part”. A polymer is a very long molecule that is made up of subunits called ‘monomers’. These subunits are linked together and repeat like links in a chain. Polymers are commonly found in plastics, proteins and rubber.

- The word “elastomer” is the scientific term for any type of rubber.

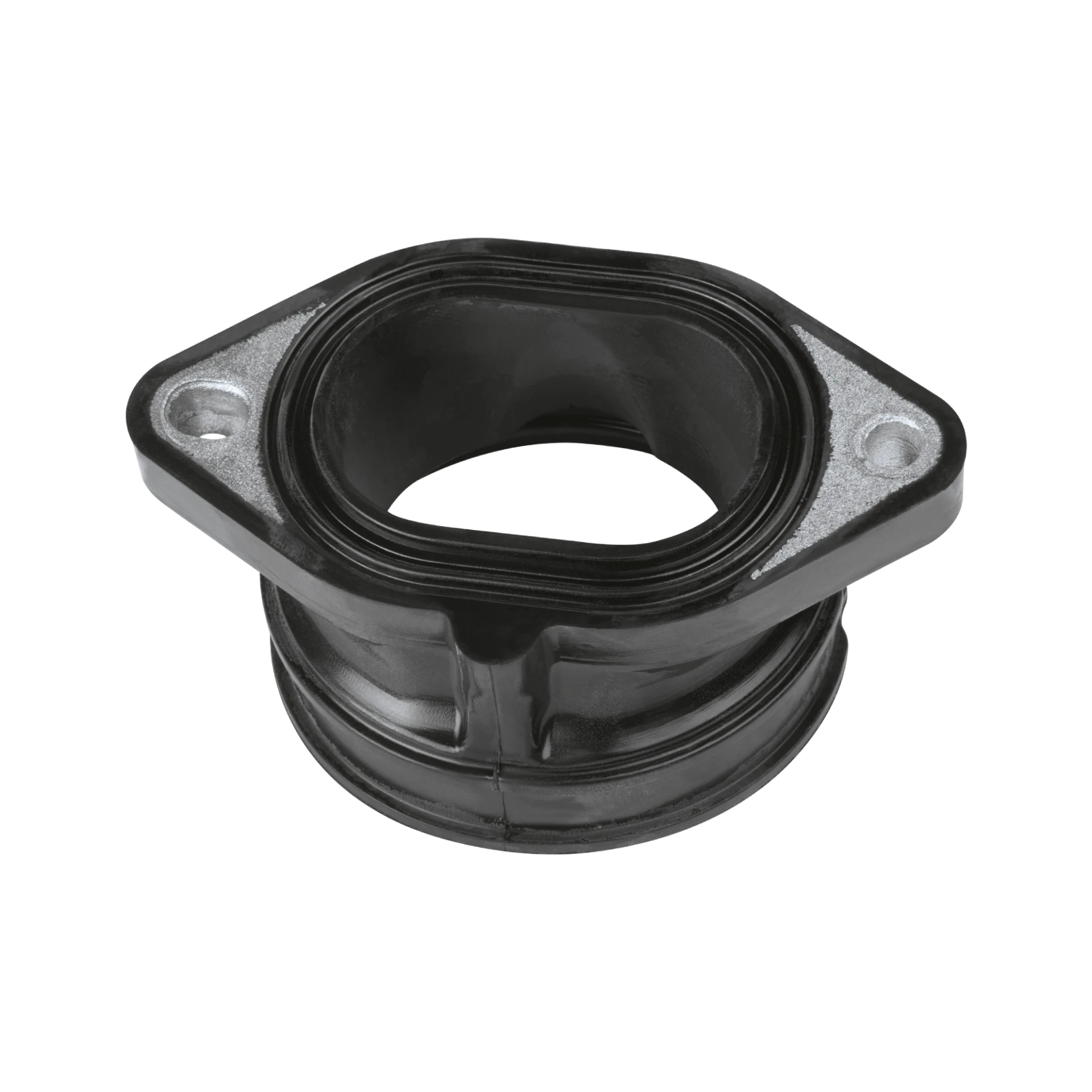

Elastomers are commonly used in the manufacture of products that need to bend, stretch, or compress repeatedly without losing their shape over time. As a result, we can find them in everyday products. In the world of sports, think hockey pucks: they need to be durable enough to withstand speed, friction, shock and more. Other common examples include gaskets, cables, pipes, certain types of flooring, anti-vibration parts, and tractor tracks.

The properties of rubber

Rubber has multiple properties that render it useful for a wide range of applications. It’s resistant to wear, heat, cold and chemicals, making it ideal for industrial applications.

Of course, the properties of rubber will depend on the polymers it’s made of. That’s why meticulous manufacturing is crucial. To be sure a product will meet your needs, you must define the conditions of use and the desired behavior of the rubber part required.

For example, if you’re looking for high resistance to heat, natural rubber is limited to 95°C, while silicone can withstand up to 300°C.

What are the different types of rubber?

There are two families of rubber: natural rubber and synthetic rubber.

Natural rubber is derived from the Brazilian rubber tree. It’s obtained by making an incision in the bark of the tree and collecting the latex that flows from it. The latex is then treated to remove water and other impurities before being sent to rubber processors like Soucy Baron.

Natural rubber is used in automotive parts, pipes, industrial equipment and more.

- Synthetic rubber is derived from petroleum and is manufactured by the petrochemical industry. These types of rubber are created using mixtures of synthetic monomers. These polymers are designed so that each family and grade of elastomer obtains the desired properties.

There are several types of synthetic rubber, each with unique properties and applications. For example, silicone is used to make gaskets due to its chemical-resistant and heat-resistant properties. Another example is fluorocarbon, which is used in high-performance applications such as aircraft engine seals.

Rubber applications

Rubber is found in a wide range of products and applications, from consumer to industrial.

Here are some applications where rubber is used:

- Agricultural industry: tracks, tires, undercarriages.

- Heavy-equipment construction: bolter spring suspension, electronic isolators, rubber bumpers.

- Motor vehicle industry: tires, transmission belts, suspension parts, gaskets, pipes, door trims.

- Aerospace industry: gaskets, thermal insulation, support parts.

- Oil industry: gaskets, pipes, seals in oil drilling machinery and equipment.

- Mining industry: protective coverings, pipes in mines.

These are but a few of the common industrial uses of rubber. It’s a versatile material with a host of practical properties that make it both customizable and invaluable.

Whatever your needs, the solution is rubber!

Custom rubber manufacturing, step by step

In its raw state, rubber isn’t particularly effective. To obtain the desired properties, rubber needs to be blended with other ingredients and prepared in a specific way. These 4 steps expose rubber’s performance and benefits:

1. Polymer chemistry

Synthetic rubber is made using basic monomers, such as styrene and butadiene, acrylonitrile and butadiene, or ethylene and propylene, which are combined to create a copolymer (what’s polymer chemistry without a bunch of complex names and elements!). Scientists create different monomer combinations until the ideal one is obtained for the customer’s needs.

2. Mixing

Natural and/or synthetic polymers and ingredients are combined in an industrial mixer to create a uniform paste. The mixture may contain ingredients such as stabilizers, vulcanizing agents, reinforcing fillers and plasticizers to enhance the properties of the rubber.

3. Molding

The mixture is then hot-molded into the desired shape. At Soucy Baron, rubber can be molded using 3 different processes: compression, injection and transfer.

- Compression molding is done by compressing and heating a rubber preform in the mold.

- Injection molding is done by injecting preheated, pressurized rubber into a mold.

- Transfer molding is something of a hybrid of these two, i.e., a rubber preform is heated and compressed, and the compressed rubber is then injected into the mold.

4. Vulcanization

To give rubber its final properties, it must be vulcanized in the mold. Vulcanization is a process of heating the rubber mixture in the presence of a vulcanizing agent, such as sulfur, to create chemical bonds between the different polymer chains present in the rubber. Vulcanization makes rubber stiffer and more resistant to permanent deformation.

- The American chemist Charles Goodyear invented the vulcanization reaction by accident in 1839, when a piece of rubber containing sulfur fell onto a hot stove.

After these steps, a rubber compound can be processed into a wide variety of finished products to meet the needs of different industries. The manufacturing steps may vary depending on the type of rubber and its end use.

Soucy Baron, your elastomer expert

Rubber is a versatile material with many properties that make it essential in a wide variety of applications. It is an extremely durable, elastic material that can be customized.

As rubber specialists for more than 50 years, our teams can create unique rubber solutions specially adapted to the needs of our customers.

At Soucy Baron, we’re proud and pleased to share our expertise in polymer chemistry. From the idea of a project to production and final delivery, we’re with our customers every step of the way.

Searching for a customized rubber solution adapted to your core business? For high-performance and high-quality rubber parts customized to your needs, Soucy Baron’s expertise is the solution.

Searching for a customized rubber solution adapted to your core business? For high-performance and high-quality rubber parts customized to your needs, Soucy Baron’s expertise is the solution.

Soucy Baron is not simply a manufacturer of elastomer parts; We are an end-to-end logistics partner, dedicated to the success of your project above all else. Working with Soucy Baron means you’ve got a partner who understands your challenges.