How do we create rubber with unique properties and develop solutions that are tailored to the specific needs of each client?

It all starts at Soucy Techno in Sherbrooke where we produce rubber from carefully crafted formulas.

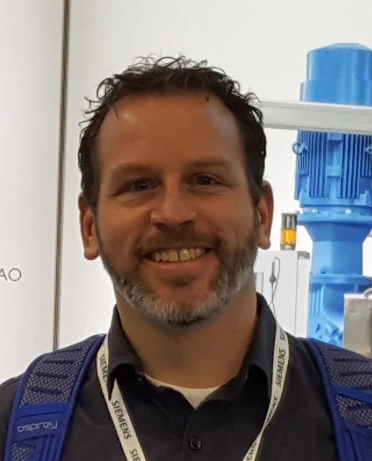

Denis Dubé is a compound specialist. He says every component that goes into the final product is carefully selected keeping the client’s requirements in mind.

In fact, he says there is no “one size fits all” formula when it comes to rubber, but rather endless possible combinations.